search

Mining Environmental Assessment & Compliance Monitoring

We bridge the critical gap between mining operational demands and environmental stewardship, delivering a data-driven foundation for responsible resource extraction. By integrating our proprietary AIMS Multi-Sensor Aerial System with Swift4D Analytics Platform and AI-powered insights, we drive a paradigm shift from reactive, manual inspections to a predictive, continuous monitoring model. This approach empowers mining companies and regulators to proactively mitigate environmental impacts, ensure strict compliance, optimize closure planning, and safeguard ecological and social licenses to operateвҖ”all through transparent, verifiable data that underpins sustainable mining practices.

Our Differentiated Solution Framework

1. High-Fidelity Baseline & Impact Quantification

A credible environmental management system begins with an accurate, measurable baseline. Traditional methods often rely on outdated maps or incomplete datasets, limiting impact assessment accuracy.

The AIMS Multi-Sensor Advantage:

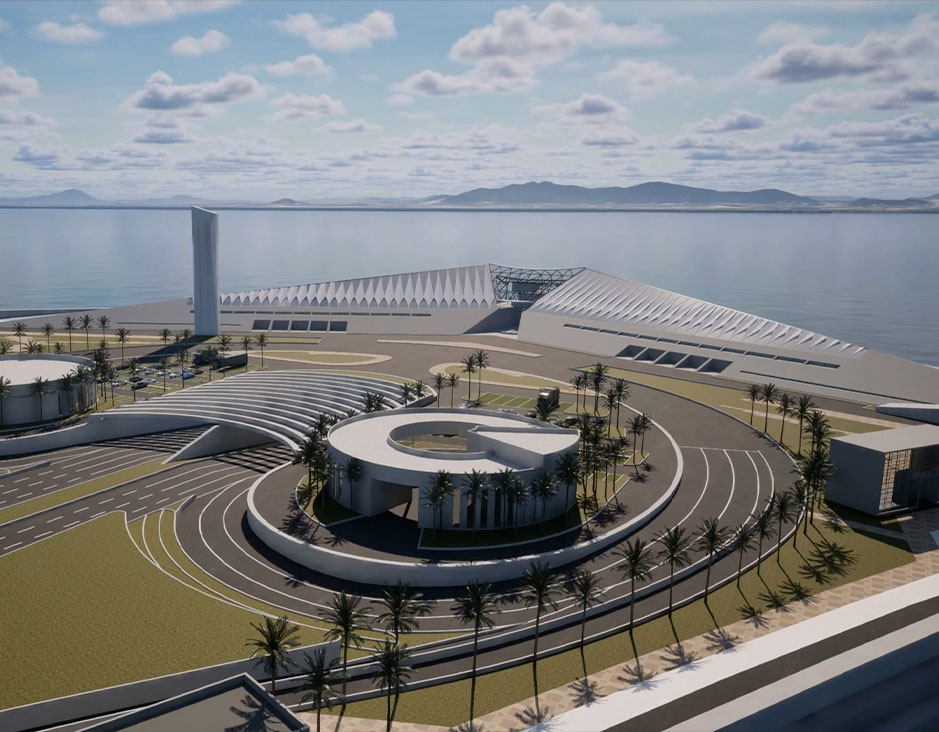

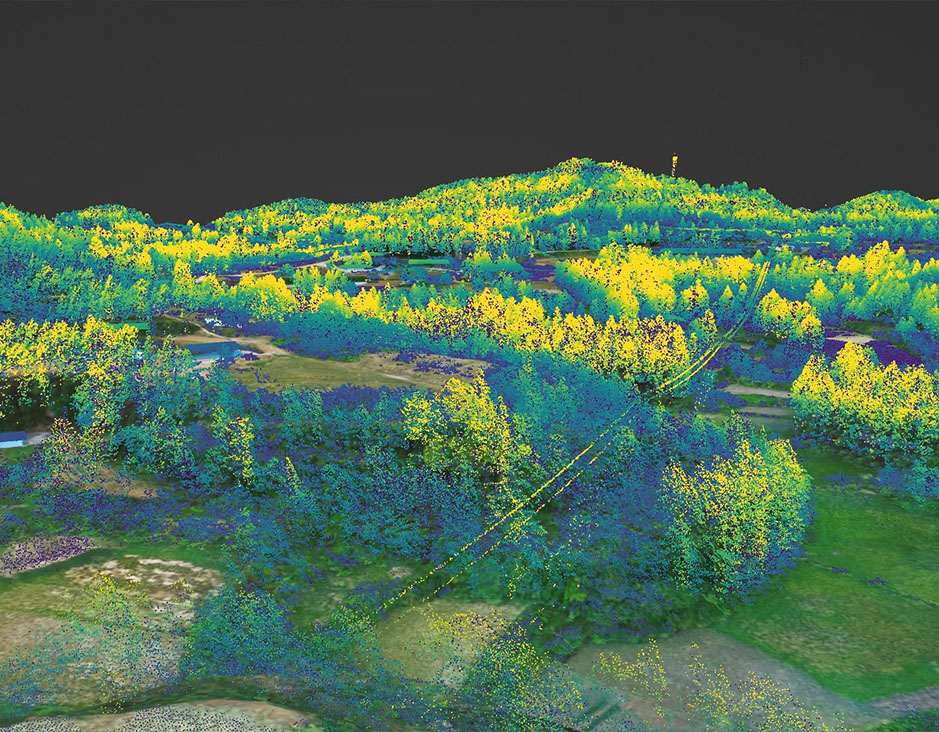

Our proprietary AIMS system captures synchronized high-resolution RGB, multispectral, thermal, and LiDAR data in a single mission, generating a centimeter-accurate 3D Digital Twin of the site before operations commence.

Quantifiable Environmental Metrics:

This digital twin establishes definitive pre-mining conditions for topography, vegetation health (NDVI), surface hydrology, and land cover, creating a legally defensible benchmark for Environmental Impact Assessments (EIAs) and future change tracking.

Continuous Multi-Temporal Analysis:

Through regular aerial surveys and the Swift4D platform, we automate change detection over time, precisely measuring volumetric extraction, stockpile growth, deforestation, and landform evolutionвҖ”supporting transparent progress and impact reporting.2. AI-Powered Compliance & Illegal Activity Surveillance

2. AI-Driven Compliance Surveillance & Unauthorized Activity Detection

Manual monitoring is inefficient, inconsistent, and often inadequate for large or remote mining concessions, increasing compliance risk and potential liabilities.

Automated Boundary & Depth Control:

Our SwiftAI algorithm suite continuously compares the latest site digital twin against the permitted geofenced concession area and approved mine plans. It automatically flags over-boundary mining, over-depth extraction, and other spatial violations in near real-time.

Continuous Operational Auditing:

The system provides persistent oversight, detecting unauthorized infrastructure, off-plan waste disposal, and other permit breachesвҖ”generating an immutable digital audit trail for internal and regulatory review.

From Reactive to Preventive Compliance:

This enables a shift from a вҖңdetect and penalizeвҖқ approach to a вҖңprevent and correctвҖқ model, allowing timely intervention before violations escalate.

3. Proactive Environmental & Geohazard Monitoring

Mining activities can alter terrain stability and affect surrounding ecosystems. Early detection is key to preventing environmental incidents and ensuring long-term site integrity.

Ecosystem Health Surveillance:

We track key indicators such as vegetation stress, dust emission spread, and water quality changes around the mine site, delivering data for environmental management plans, community reporting, and ESG disclosures.

Slope Stability & Ground Deformation Monitoring:

Using sequential LiDAR and InSAR data, our platform performs millimeter-level deformation analysis on critical infrastructure including tailings dams, pit slopes, and waste dumps. This supports early-warning systems and proactive geotechnical risk management.

Unified Risk Intelligence Dashboard:

All environmental, safety, and stability metrics are visualized in an integrated dashboard, enabling prioritized action and demonstrating operational due diligence to regulators and stakeholders.

Application Scenarios & Client Value

Application Scenario | Pain Points Addressed | Feiyan's Solution & Deliverables | Value to Client |

EIA & Baseline Establishment | Lack of accurate pre-mining data; subjective impact reporting; delays in permitting. | High-resolution pre-operational Digital Twin; quantified baseline report with measurable environmental metrics. | Defensible, science-based permitting; clear stakeholder communication; reliable foundation for impact tracking. |

Automated Compliance Monitoring & Reporting | Costly manual inspections; inability to demonstrate continuous compliance; risk of undetected violations. | 24/7 automated aerial surveillance; real-time alerts on boundary/depth breaches; scheduled compliance audit reports with evidence. | Lower cost of compliance; reduced violation risk; audit-ready documentation; strengthened regulator trust. |

Tailings Dam & Pit Wall Stability | Risk of catastrophic failure; hazardous manual monitoring; limited data frequency and coverage. | Millimeter-precision InSAR & LiDAR monitoring; displacement trend analysis; automated early-warning alerts. | Enhanced safety & risk mitigation; supports compliance with Global Industry Standard on Tailings Management (GISTM); protects lives and assets. |

Mine Closure & Rehabilitation Planning | Difficulty in objectively measuring rehab progress; challenges in securing financial assurance release. | Rehabilitation tracking against planned landforms; quantitative vegetation recovery (NDVI) and erosion stability metrics. | Data-driven closure certification; successful bond release; demonstrated post-mining environmental commitment. |

AIMS

AIMS AIMS-H Long Focus

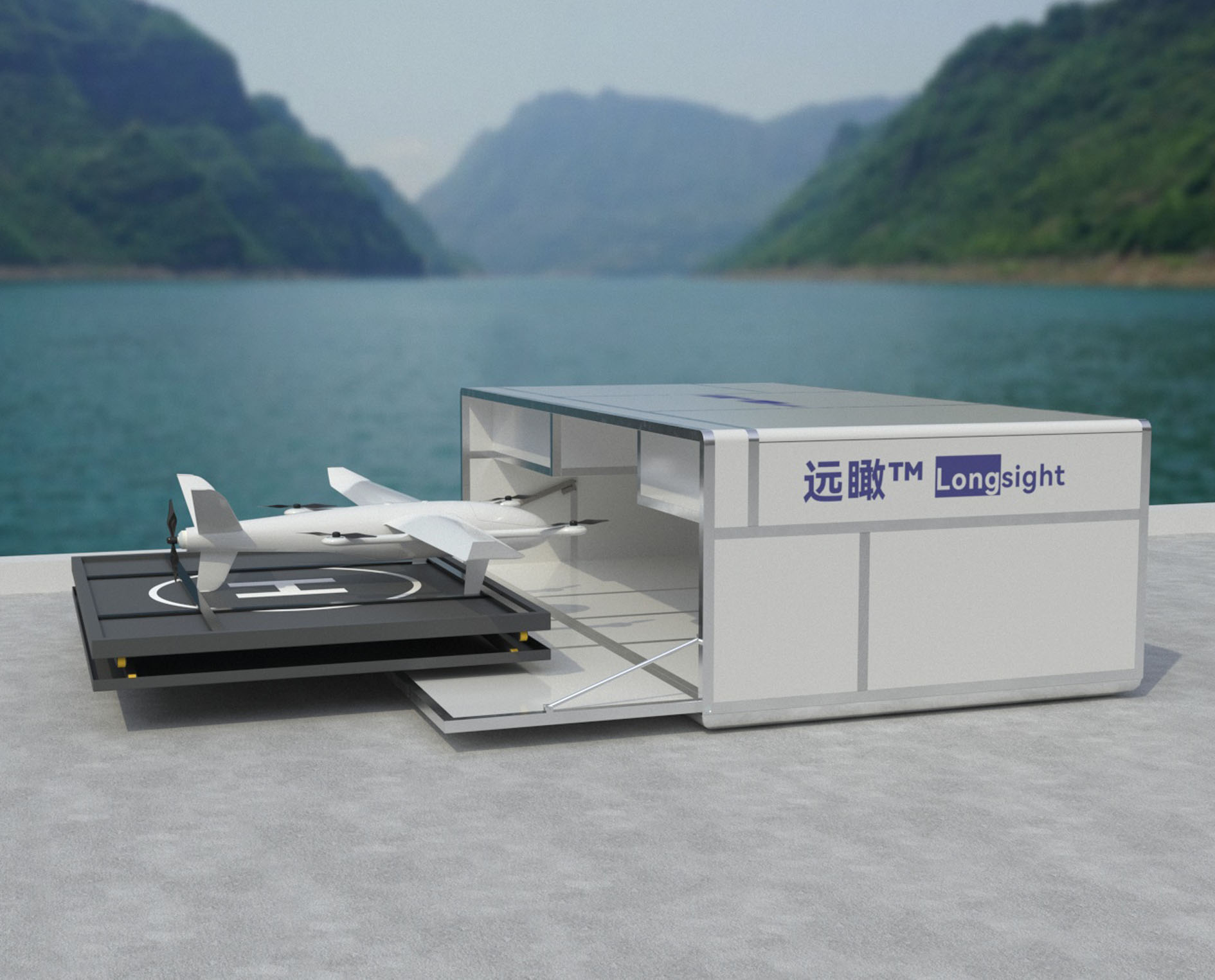

AIMS-H Long Focus Farsightв„ў System

Farsightв„ў System Riegl VQ-1560i

Riegl VQ-1560i Riegl VQ-780II

Riegl VQ-780II UltraCam Eagle M3

UltraCam Eagle M3 Y-1 VTOL UAV

Y-1 VTOL UAV Aerial Acquisition

Aerial Acquisition UAV Acquisition

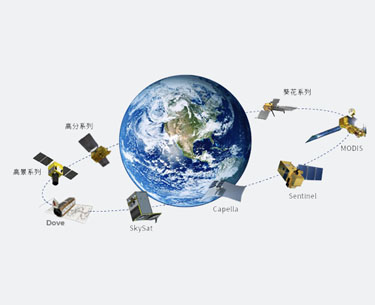

UAV Acquisition Satellite Acquisition

Satellite Acquisition Field Acquisition

Field Acquisition Integrated

Integrated LiDAR

LiDAR Orthophoto

Orthophoto DEM

DEM DTM/DSM

DTM/DSM 3D Mapping

3D Mapping Topographic

Topographic Infrared

Infrared Feature Extraction

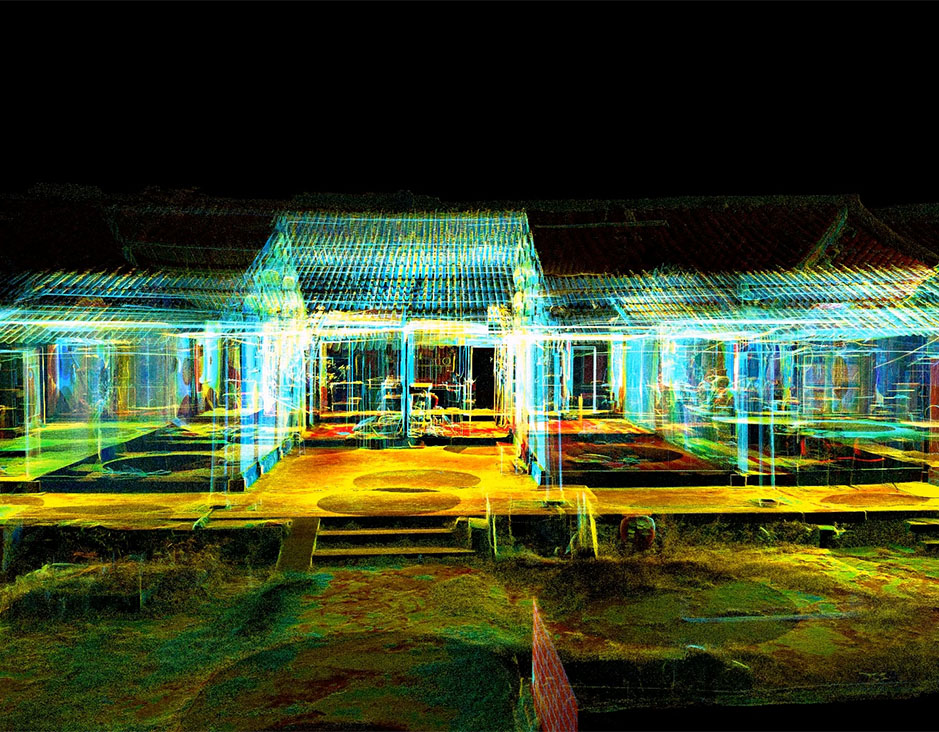

Feature Extraction BIM

BIM Transportation

Transportation Water

Water power

power  Forestry

Forestry Agriculture

Agriculture Mines & Quarries

Mines & Quarries Heritage Buildings

Heritage Buildings About feiyan

About feiyan Recognition

Recognition Cases

Cases